Precision and Reliability through Secondary Encoders

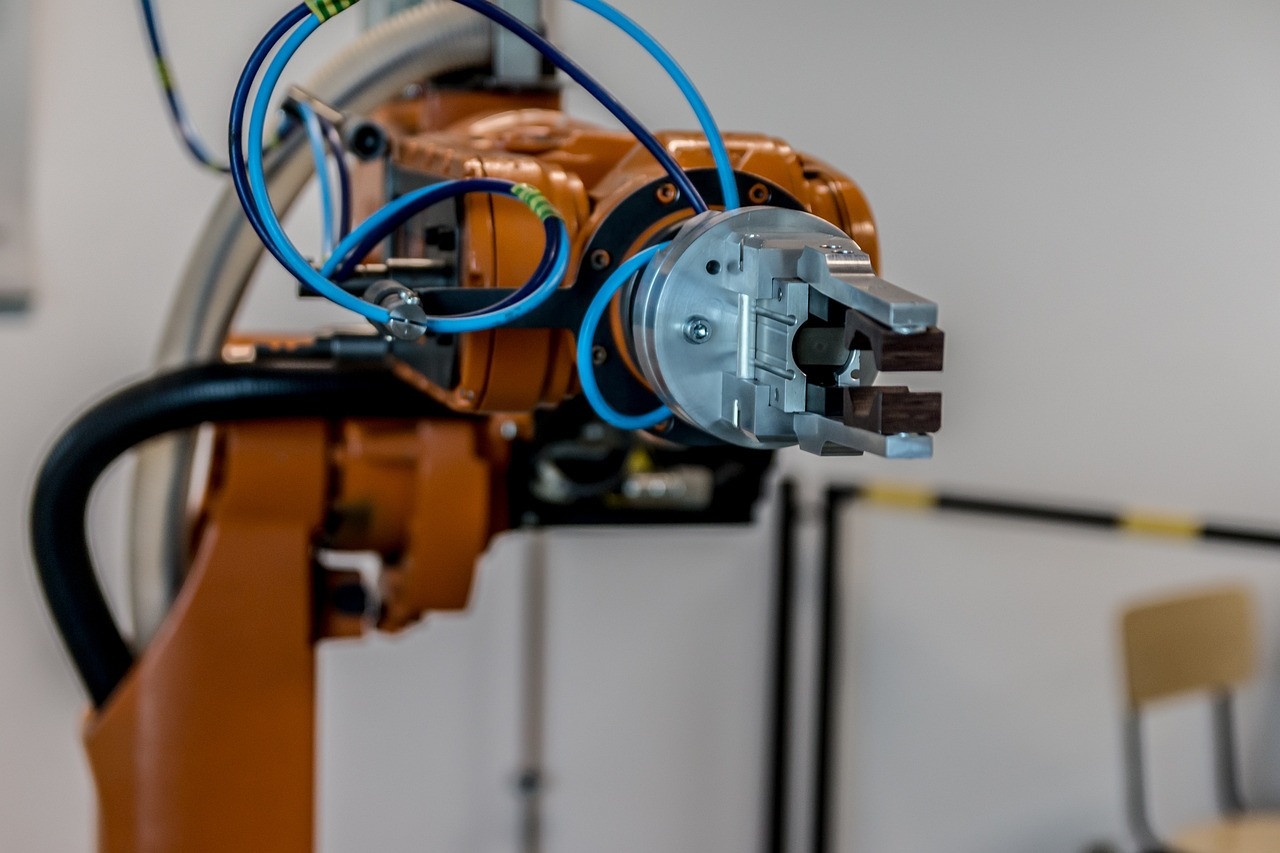

A key element that sets MABI Robotic’s arm apart from competitors is the use of secondary encoders. These advanced position sensors monitor the movement of each robotic arm drive, ensuring highly accurate motion tracking and increased structural stability. Compared to traditional robots, this innovation allows for precise execution of even the most demanding CNC (computer numerical control) operations, in both additive and subtractive processes. This flexibility makes robotic arms ideal for tasks such as milling and material processing, enhancing productivity and ensuring reliable outcomes.

The MAX Series – Flexibility and Power in One

One of the most notable representatives of MABI’s portfolio is the MAX series of robots, including the compact yet powerful MAX-100-2.25-P. This robotic arm, with an impressive payload capacity of 100 kg and a reach of 2.24 meters, stands out for its precision and performance, making it a perfect solution for companies in need of high-quality manufacturing tools. This model is especially valued in processes requiring both precision and strength, making it a key tool in industries such as automotive, aerospace, and heavy machinery.

Currently, MABI is developing an even more advanced version of this series – the MAX-200-2.5-P, set to be released in late 2024. This new model, equipped with an increased payload and extended reach, is designed to meet the most demanding manufacturing requirements, offering unprecedented capabilities for industrial processing.

Applications of MABI Robots in Industry

MABI robots are used in a wide range of manufacturing processes. Thanks to their exceptional precision, they are ideal for operations such as milling, cutting, and welding, where every millimeter can determine the quality of the final product. Industries benefiting from MABI robots include:

- Automotive industry – precise machining of engine parts, bodies, and other components.

- Aerospace industry – production of highly advanced, lightweight, and durable parts.

- Machinery manufacturing – construction of large-scale machines and equipment requiring precise components.